產(chǎn)品展示

- 電話總機:400 8825788

- 傳真:0536-6512296

- 售后:13563697757

- 郵箱:250158177@qq.com

- 地址:山東省濰坊市諸城市龍都街道西外環(huán)路中段西側

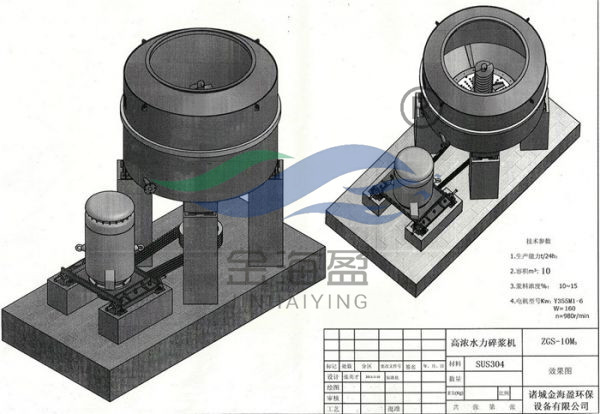

液壓高濃磨漿機 Hydraulic pressure High consistency refiner

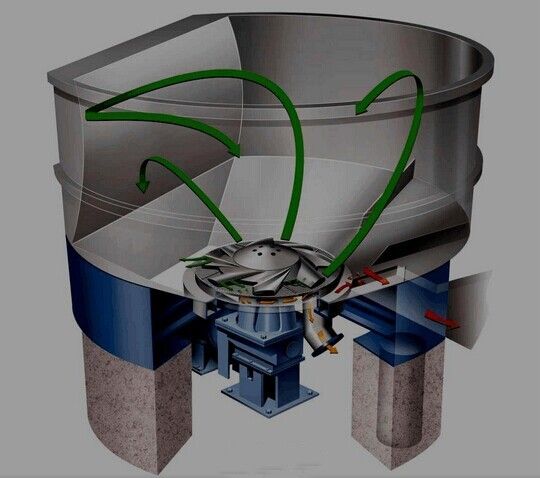

二、理想的疏解打漿原理:

高濃度磨漿過程,植物纖維在兩磨盤之間撐起兩面磨盤的間隙,使磨盤沒有真正碰到一起,主軸上的移動磨盤有很高的推力,在1500轉的高轉速下壓潰疏解纖維,所以剪切力降低,保證纖維不被切斷。植物秸稈纖維化的過程來自于兩副磨盤的強力壓潰和纖維之間的相對搓揉,使纖維分絲帚化,完成疏解磨漿過程。高濃度磨漿機對物料適應范圍廣,無論是木材,竹子、稻草、麥草、蔗渣、廢紙等原料,都能夠以其較高的線速度和適當?shù)哪テg隙疏解分離成優(yōu)質的纖維原料。

一、Ideal principle of defibering and beating:

In the process of high-concentration pulping, the plant fiber propped up the gap between the two millstones, so that the millstones did not really touch each other. The moving millstones on the spindle had high thrust, which crushed and loosened the fiber at a high speed of 1500 revolutions, so the shear force was reduced, and the fiber was not cut off.。The process of plant straw fibrosis comes from the strong crushing of two grinding discs and the relative rubbing between fibers, which makes the fibers split and broom, and completes the process of defibering and refining。High-concentration refiners have a wide range of applications to materials. No matter wood, bamboo, rice straw, wheat straw, bagasse, waste paper and other raw materials, they can be separated into high-quality fiber raw materials with high linear speed and proper grinding gap。

三、與低濃磨漿機的比較有明顯的優(yōu)點:

3.1、節(jié)能:噸漿電耗節(jié)省20﹪~40﹪.

3.2、節(jié)水:噸漿節(jié)省用水60﹪以上.

3.3、高效:能使纖維物理強度指標提高10﹪~20﹪.

3.4、柔性打漿:能使原料在含水率極低的狀態(tài)下進行擠壓、摩擦、揉搓等做功狀態(tài)疏解成優(yōu)質的纖維,從而使植物秸稈充分分絲、帚化、纖維化。

3.5、高濃疏解纖維優(yōu)點:秸稈原料含水率低,在高壓搓揉作用下迅速升溫,改變纖維結構,分離纖維束,將木質素在助劑軟化分解過程中利用磨盤間磨齒的壓潰剝離作用,將木質素剝離至纖維表面,與纖維分離,提高纖維質量,降低木質素對纖維的影響。

3.6、潤滑和冷卻:具有特別的軸承稀油潤滑和軸承稀油、水雙冷卻系統(tǒng),有效保證軸承的潤滑和冷卻,保證主機正常運行。

3.7、本機采用獨特的機械傳動和液壓設計,優(yōu)化的磨片組合,簡捷的磨片間隙調節(jié)方式,操作方便靈活、運行穩(wěn)定可靠、維修方便快捷、外形美觀大方。充分體現(xiàn)了人機合一的完美組合。

三、Compared with low consistency refiner, it has obvious advantages:

3.1、Energy saving: the power consumption per ton of pulp is saved by 20%~40%.

3.2、Saving water: saving water by over 60% per ton of pulp;

3.3、High efficiency: it can improve the physical strength index of fiber by 10%~20%.

3.4、Flexible beating: The raw materials can be extruded, rubbed, kneaded, etc. under the extremely low water content to be decomposed into high-quality fibers, so that the straw can be fully divided, brushed and fiberized.

3.5、Advantages of high-consistency coarse grinding and shredding: the moisture content of straw raw materials is low, and the temperature rises rapidly under the high-pressure thrust and kneading of two millstones, realizing a short cooking process. At high temperature, the fiber becomes soft and tough and will not be cut. Extruding lignin from fiber can improve fiber quality and reduce the influence of lignin on fiber.

3.6、Lubrication and cooling: It has special bearing lubrication and cooling system, oil cooling and water cooling, and dual cooling system, which effectively ensures the service life of bearings and the normal operation of the main engine。

3.7、This machine adopts unique mechanical transmission and hydraulic design, unique combination of grinding plates, simple adjustment mode of grinding plate gap, convenient and flexible operation, stable and reliable operation, convenient maintenance and beautiful appearance. Fully embodies the perfect combination of man-machine integration.