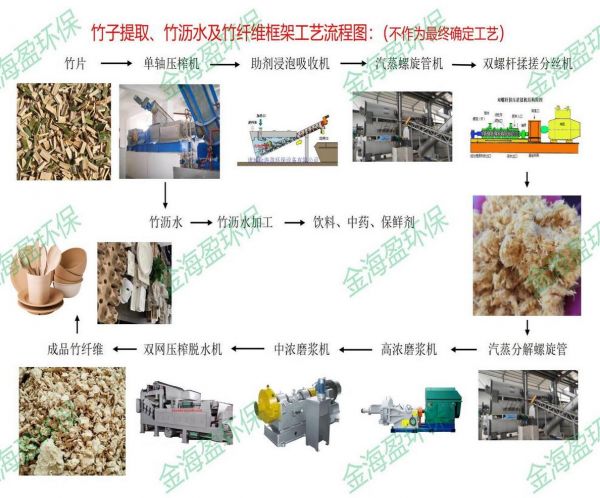

產(chǎn)品展示

- 電話總機:400 8825788

- 傳真:0536-6512296

- 售后:13563697757

- 郵箱:250158177@qq.com

- 地址:山東省濰坊市諸城市龍都街道西外環(huán)路中段西側

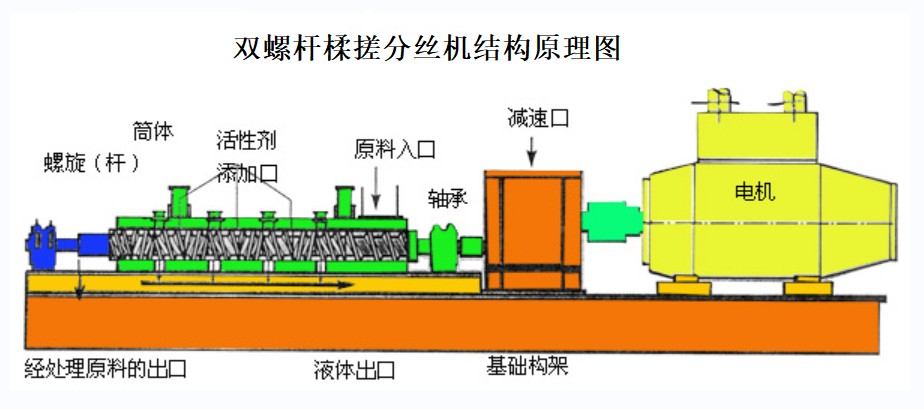

雙螺桿揉搓分絲機

第一章、概述:

80年代初,國外有學者指出,木材纖維軸向受壓時產(chǎn)生的皺曲作用,使纖維分離,即利用木材纖維軸向受壓制漿時,可在低能耗下,生產(chǎn)出纖維長而結合力好的漿。雙螺桿揉搓分絲機就是基于這種理論,使纖維離解和細纖維化,纖維切短少, 制得高質(zhì)量的漿料。

一、Design principle and performance introduction:

In the early 1980s, foreign scholars pointed out that fiber separation was caused by the buckling of wood fibers under axial compression, that is, when wood fibers were used for axial compression pulping, pulp with long fibers and good binding force could be produced with low energy consumption。Based on this theory, the twin-screw kneading and splitting machine makes the fibers dissociate and fibrillate, and the fibers are cut short to produce high-quality pulp。

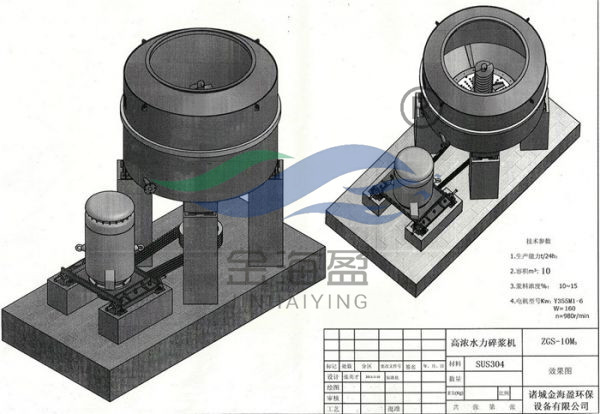

第二章、雙螺桿楺搓分絲機結構組成:

雙螺桿楺搓分絲機由電機、特種齒輪箱、組合式螺旋件、半開式殼體、喂料器、液壓系統(tǒng)、潤滑系統(tǒng)、藥液(或水)注入系統(tǒng)、廢液回收系統(tǒng)、機座等組成。

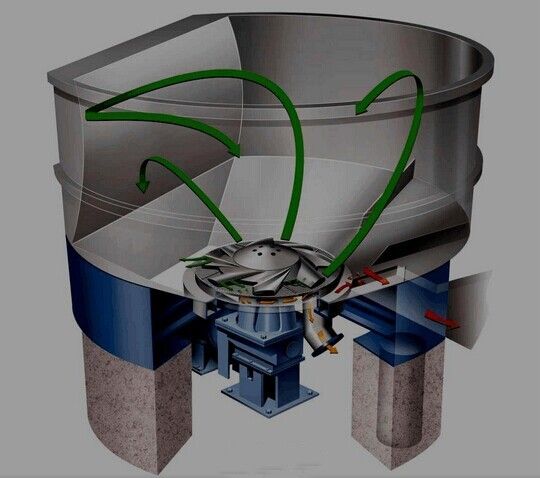

其工作部分是由一對平行、嚙合且同向旋轉的積木組合式螺旋件和內(nèi)裝可拆襯套的半開式殼體組成。殼體上設有液體注入孔和用于提取液體的過濾器。螺旋件可根據(jù)工藝需要組成多段漿料輸送區(qū)、擠壓區(qū)、擠碾撕裂揉搓區(qū)、浸漬處理區(qū)、均化混合區(qū)。

2.1、輸送區(qū):原料被強制性高效率輸送;

2.2、擠壓區(qū):增加原料密實度,同時脫水濃縮;

2.3、擠碾?yún)^(qū):原料受到擠碾、撕裂和均化,并將機械能轉變成熱能,使原料迅速升溫軟化;

2.4、浸漬洗滌區(qū):加入藥液并進行高濃混合,通過摩擦作用使得漿料和藥液充分作用;若加入清水即可完成洗滌作用;

2.5、均化區(qū):漿料進一步受到擠碾、磨解和混合升溫。

第三章、雙螺桿楺搓分絲機可完成如下功能:

3.1、磨漿——兩根相互嚙合的螺旋件就象一臺高效率的螺桿泵一樣將漿料強制性的定向(纖維軸向)擠壓和輸送,原料在擠碾?yún)^(qū)纖維軸向受到較大的擠壓力和揉搓作用,有利于纖維軸向產(chǎn)生裂紋,強化了藥液滲透和纖維分離作用,完成磨漿功能。

3.2、化學浸漬——利用該機可進行多種化學處理并能將藥液注入殼體不同的工作區(qū)域。它是高效率的高濃混合器,漿料通過擠碾?yún)^(qū)時被強有力地揉搓。同時,溫度和壓力的作用可使?jié){料在高濃下加快化學反應。

3.3、洗滌——該機在高壓區(qū)裝備有效的過濾器,可對原料磨解的同時進行洗滌,可按工藝要求設置多段洗滌區(qū)。高的擠壓力和有效的揉搓作用可實現(xiàn)高效率的洗滌,同時還可節(jié)約清水、降低排污量。

3.4、漂白——可作為高濃反應器完成漿料和漂液的高濃混合。具有高濃(25-35%)、高效、快速漂白的優(yōu)點。并可節(jié)約漂白劑和其他化學藥品。

3.5、由于磨漿機理的不同,雙螺桿揉搓分絲機磨漿過程中纖維長度的降低幅度遠小于盤磨機,但對纖維初生壁(P層)和次生壁外層(S1層)卻有極好的破壞效果,這有利于成漿和提高紙的質(zhì)量。

三、The twin-screw extruder can perform the following functions:

3.1. Pulping: The combined shafts of two mutually meshed spiral parts are like an efficient screw pump. During the process of forcibly extruding and conveying raw materials, wood chips, bamboo chips and other raw materials are subjected to greater extrusion force and kneading in the fiber axial direction in the extrusion grinding area, which is beneficial to fiber axial cracking, strengthening the penetration of liquid medicine and fiber separation, and completing the grinding function of pulp。

3.2、Chemical impregnation: This machine can be used for a variety of chemical treatments, and can inject liquid medicine into different working areas of the shell. It is a high-efficiency high-consistency mixer, and the slurry is vigorously kneaded when it passes through the squeezing zone. At the same time, the temperature and pressure can accelerate the chemical reaction of the slurry at high concentration。

3.3、Washing: The machine is equipped with an effective filter in the high pressure area, which can be used to grind chemical mechanical pulp or semi-chemical pulp and wash it at the same time, and multiple washing areas can be set according to the process requirements. High extrusion force and effective kneading can realize efficient washing, and at the same time, it can save clean water and reduce the amount of sewage。

3.4、Bleaching section: It can be used as a high concentration reactor to complete the high concentration mixing of slurry and bleaching solution. It has the advantage of rapid bleaching under high concentration. And can save bleach and other chemicals。

Due to the different design principles of the equipment, the reduction of fiber length in the pulping process of the double-screw kneading separator is much less than that of disc refiner, but it has excellent destructive effect on fiber primary wall (P layer) and secondary wall outer layer (S1 layer), which is beneficial to pulping and improving paper quality。

第四章、雙螺桿揉搓分絲機的特點:

4.1、雙螺桿楺搓分絲機可替代傳統(tǒng)的制漿打漿漂白過程,完成浸漬、蒸煮、漂白、磨解、洗滌等工序。

4.2水、電、汽消耗較傳統(tǒng)制漿生產(chǎn)線大幅度降低。

4.3、磨漿、制漿濃度為25-40%。制化機漿噸漿耗水10-14立方米,為傳統(tǒng)用水量10%左右。電能消耗可較傳統(tǒng)生產(chǎn)降低20-50%。制漿和磨漿過程中由于漿料磨擦產(chǎn)生大量熱,可滿足蒸解或漂白所需溫度,因此制漿過程可不加蒸汽或少加蒸汽。